Imagine a Fabric that Cools Itself… and the Person Wearing It

It’s summertime and it’s hot. In some places it’s really hot.

On several days this year, the temperature reached upwards of 120 degrees Fahrenheit in Death Valley, which sits on the California/Nevada border. There were more than two weeks of temperatures above 90 degrees Fahrenheit in the Southeast.

You get the sweaty and uncomfortable idea.

Now, imagine if the shirt on your back could help you cool off. Researchers at the Wilson College of Textiles at NC State are working on smart fibers to make that possible.

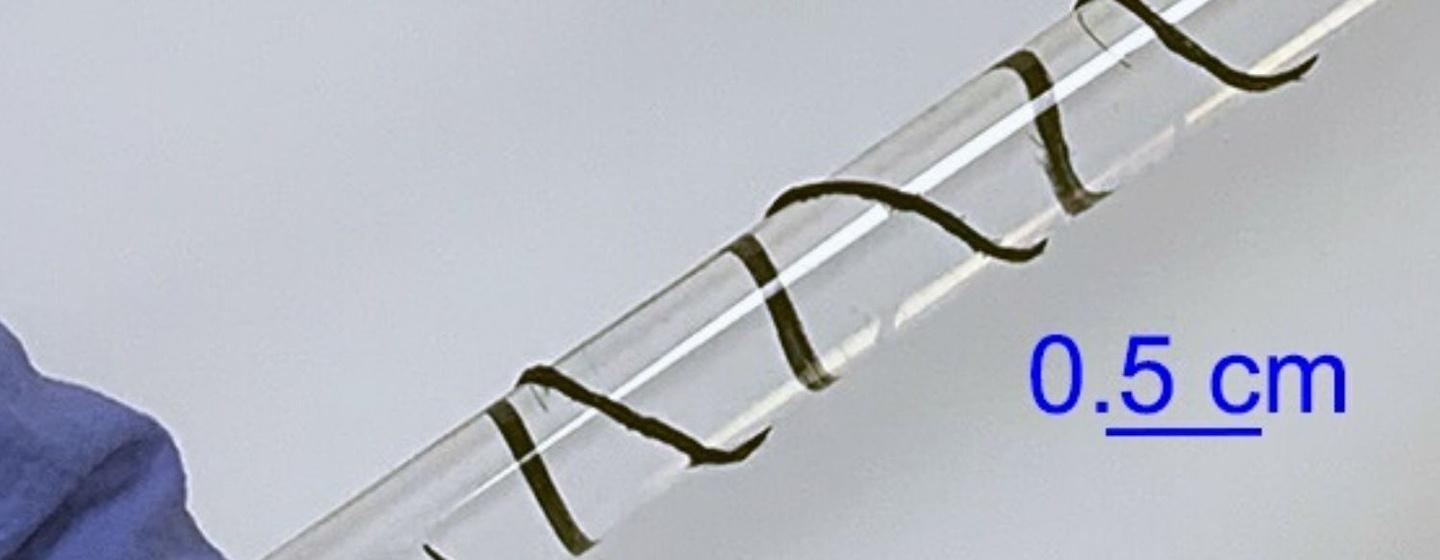

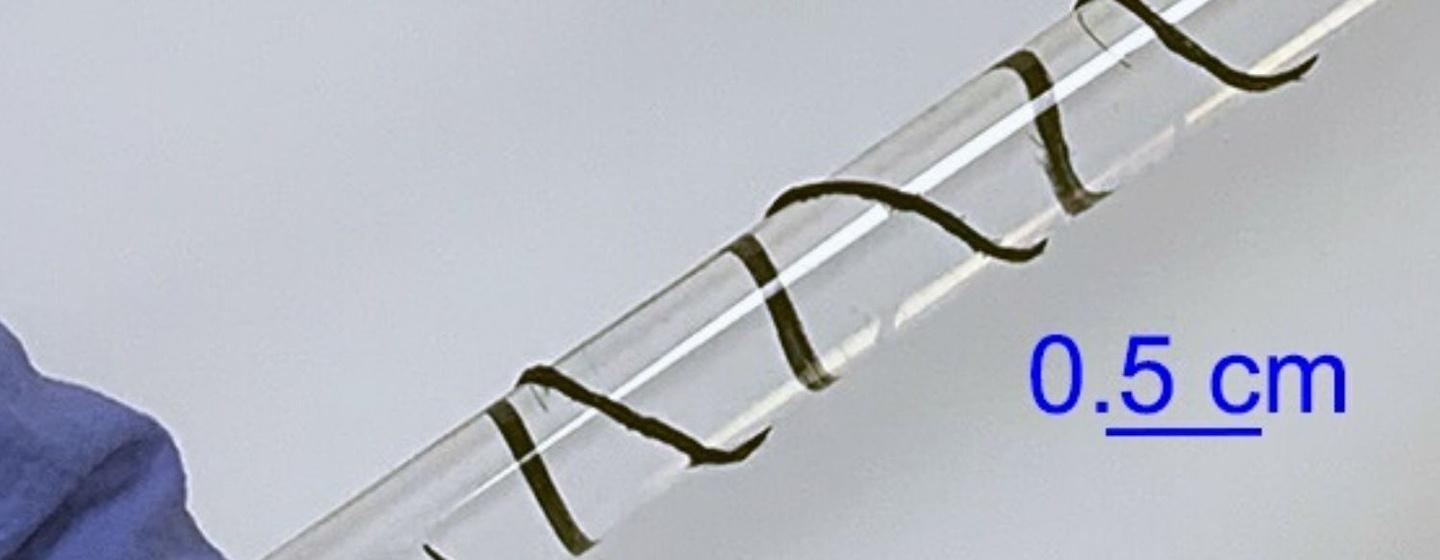

The project involves carbon nanotubes (CNT). Those are sheets of carbon atoms rolled up into cylinders hundreds of times thinner than human hair

The idea is to create a new, flexible material with thermoelectric properties, and the nanotubes appear to make that possible. Researchers have found that CNT film has a combination of thermal, electrical and physical properties that could be woven into next-generation smart fabrics.

“Many researchers are trying to develop a material that is non-toxic and inexpensive, but at the same time is efficient at heating and cooling,” said Tushar Ghosh, a professor in the Wilson College of Textiles, “Carbon nanotubes, if used appropriately, are safe, and we are using a form that is relatively inexpensive. So, it’s a potentially more affordable thermoelectric material that could be used next to the skin.”

The concept of self-cooling fabrics isn’t new, but existing thermoelectric materials tend to be heavy and brittle. It’s not what you want in a shirt.

“We want to integrate this material into the fabric itself,” said Kony Chatterjee, a PhD student in fiber and polymer science at NC State. “Right now, the research into clothing that can regulate temperature focuses on integrating rigid materials into fabrics and commercial wearable thermoelectric devices on the market aren’t flexible either.”

Which is why the carbon nanotubes are intriguing. First, the nanotubes are flexible. The thin film of nanotubes is woven into thread that can used in existing textile manufacturing processes. That’s important, because needing to change current processes, the thread could be sewn into fabrics to give temperature-regulating properties

Researchers also found CNT’s have properties that would draw heat away from the body when an external current is applied.

“Think of it like a film, with cooling properties on one side of it and heating on the other,” Ghosh said.

Researchers tested a prototype material and found it could cool a surface by about 1.8 degrees Fahrenheit when powered by a coin battery of only 5 volts. That might not sound like a lot, but even that small difference can be noticeable on a person’s skin.

Think of the times when you’ve adjusted the thermostat up or down by just one degree. It makes a difference.

There is still a long way to go, but Ghosh says the ultimate goal for the project is to design a smart fabric that can both cool and heat the wearer, depending what is needed. That could have major implications in health care as well as protective gear for emergency workers.

For now, the research team has designed a material that is soft, flexible, easy to fabricate and has the thermoelectric and thermodynamic properties that are needed. The next goal is to scale up manufacturing material to make it more attractive to producers.

Someday in the future, hot days won’t seem quite so bad.